Services

Featured Categories

New Equipment

At Alta Material Handling, we partner with best-in-class brands like Hyster and Yale, and offer an extensive selection of new forklifts, aerial lifts, and more. As a leading material handling equipment dealer in Michigan, Northern Indiana, Illinois, Virginia, New England, and New York, we work with you to provide the right equipment at the right price. Our flexible financing and leasing options ensure you have access to the new equipment you need, while protecting your bottom line.

Used Equipment

As a premier supplier of material handling equipment in Michigan, Northern Indiana, Illinois, Virginia, New England, and New York, Alta Material Handling stocks an extensive selection of high-quality used equipment. Each piece of equipment in our inventory is thoroughly inspected by our service department to ensure it meets strict quality standards. From pre-owned forklifts to used aerial lifts, telehandlers, material handling vehicles, and more, you’ll find it at Alta Material Handling.

Lighting

We offer Industrial, Commercial & Retail Lighting Systems for Warehouses in the NY Metro area. Providing affordable energy solutions since 2004, Alta Lighting Services has the people, products and expertise to deliver results that exceed your expectations with the highest level of customer service in the industry.

Dock & Door

This division was added to meet the demands of our valued customers offering the nation-leading brands of Kelley and Serco Loading Dock Equipment to complement our material handling service and offering our customers a seamless transition with one vendor for their forklift, loading dock & overhead door needs. Throughout the years we have added significant distributor lines such as Rytec High Speed Doors, Alpine Rolling Steel Doors, and Clopay & Wayne Dalton Sectional Door.

Environmental Solutions

Alta is proud to carry Advance industrial floor cleaning equipment. Keep your floors looking their best and clear of debris with walk-behind and ride-on scrubbers, sweepers, and more. Contact your nearest Alta dealership in New York for more information.

Warehouse Solutions

Alta Material Handling offers a wide range of warehouse products to help make the best use of your storage space. Optimize efficiency with conveyor systems, hoists and cranes, racks, mezzanines, modular offices, and more. Looking to completely redesign your space or build a new warehouse? Call or visit today to speak with a specialist about creating a comprehensive space solution customized to your business needs.

Robotics

It was once said a fork truck salesman couldn’t spell AGVs. Not at Alta. We provide proof of concept, simulations, Rough order of Magnitude (ROM), installation, commissioning and service and financing, standard as our solution package. Alta has strategic partners in the AGV space who support mission critical activities. Our nationwide service organization provides service and support for our large customer base.

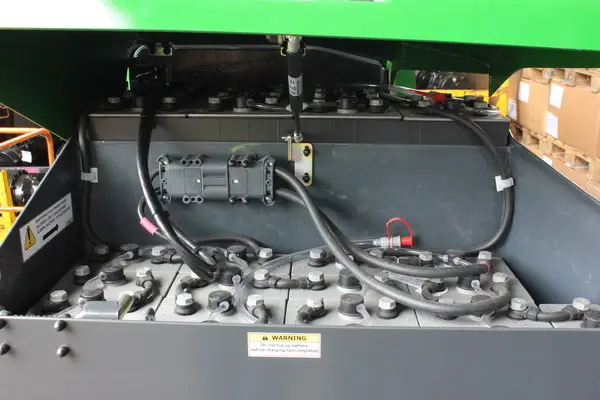

Motive Power

Alta takes all the finger-pointing away and gives you a comprehensive solution to meet your specific needs. Not all lithium is created equal, and not all lead acid batteries are created equal and not all chargers are created equal. We bust the Myths.

Equipment & Services Brochure Library

Whether you’re looking for cleaning equipment, information about robotics and automation, or an expansive range of material handling equipment, our extensive selection of equipment & services brochures is guaranteed to have what you need.